|

SP05.10 : Van an toàn vi sinh - SANITARY

Thông số chính:

Van an toàn vi sinh - SANITARY - Sanitary Safety Valve

Tư vấn , Thiết kế , Chế tạo dây chuyền – Thiết bị công nghệ , Hệ thống pha trộn - định lượng được tổng hợp từ các thiết bị công nghệ Bơm - Van - Cảm biến , Thiết bị điều khiển Allen – Bradley (Mỹ)

Hãng cung cấp :

Model :

|

|

Applications

AQ3 sanitary safety valve is a sanitary stainless steel safety valve, with safety design for equipment protection. It is installed in the discharge pressure loop in order to protect pipelines, pumps, fittings, and tanks, etc.. It is widely used in food, beverage, diary, pharmaceutical and beer industries.

Operating Principle

AQ3 sanitary safety valve calibrates a specific pressure by adjusting the gland nut of the spring. Calibration pressure is a maximum safe pressure value fixed in order to avoid equipment damage. Under normal working pressure, the valve is closed. When the pressure in the pipe system exceeds the calibration pressure, the valve is open. Thus, the pressure in the pipe system is discharged and the pipeline and equipment are protected.

|

|

AQ3 sanitary safety valve is operated by a handle. AQ3-1 series is an improved version of the AQ3 sanitary safety valve. It is equipped with a pneumatic actuator, which is convenient to carry out CIP cleaning to safety valve and pipelines.

AQ3 sanitary safety valve is a more specialized valve, and it has been checked strictly before delivery. In order to ensure conformity to the actual operation conditions, please check the valve on-site if possible.

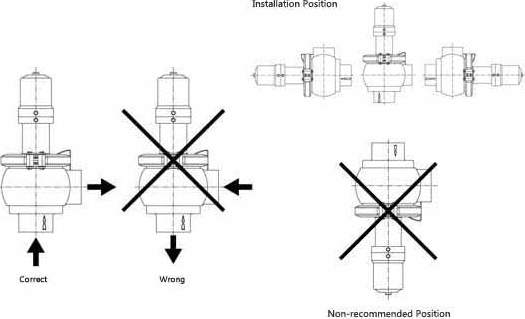

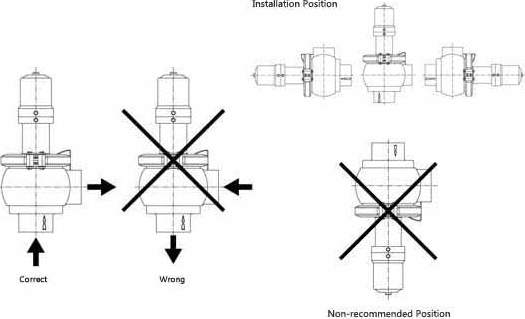

Correct Installation Method

Technical Data

| Metal material |

Product wetted

|

304L/316L (DIN-1.4307/1.4404)

|

|

Non-product wetted

|

304 (DIN-1.4301)

|

|

We can provide EN 10204 3.1B certificate.

|

| Seal material |

Standard

|

EPDM

|

|

Options

|

Silicone, PTFE, FPM, NBR

|

|

All seal materials comply with FDA 177.2600.

|

| Temperature |

Continuous working temperature

|

-20°C ~ +135°C (EPDM)

|

|

Sterilization temperature

|

150°C (Max 20min)

|

| Pressure |

Base measuring pressure

|

0~3bar/0~6bar/0~10bar (According to the role of spring)

|

|

Control air pressure

|

5~8bar

|

| Surface treatment |

Internal surface

|

Ra≤0.8µm

|

|

External surface

|

Shot blasting

|

| Connection |

Connection standards

|

Welding end: DIN 11850 series 2

|

|

Welding end: Inch pipe diameter standard

|

|

Connection methods: welding, thread, clamp, flange

|

|